Design

Using state of the art Technologies is a part of our quality policy. The use of CATIA during the part design makes is possible to attain max. productivity and creativity, from the product definition to the product in the application.

KANCA is also able to receive data in Pro/E format from the customers. Any product of KANCA appears first on the computer screens. Solid models of the products are transfered to the FEM analaysis softwares enabling the visualisation and optimization of the forming processes.

Forging processes simulation and CAD/CAM development tools, are coupled to obtain better production and design cycles. Design parameters and tuned by optimizing the die loads and material flow so possible production problems are determine beforehand. Integrating simulation, modeling and CNC production into the design process ensures the safe, high-quality production.

Material

It is vital for us to supply, produce and control all kinds of metallurgical materials of the highest quality. We guarantee the performance of the products we produce by working with the highest quality steel producers approved both in Turkey and in Europe.

On the other hand, within the framework of customer and market predictions, we plan meticulously to ensure that our supply chain continues without breaking in any way, and we respond to customer demands with optimum stocks.

Die Shop

The next most important element in producing the perfect parts is a set of dies produced correctly and accurately according to the design. Every stage of dies is designed in our CAD/CAM facilities using CATIA and the process is simulated before committing to metal.

Then, dies are manufactured using themost up-to-date CNC high speed machinery in our die shops. Dies are fully tested before moving to the production lines.

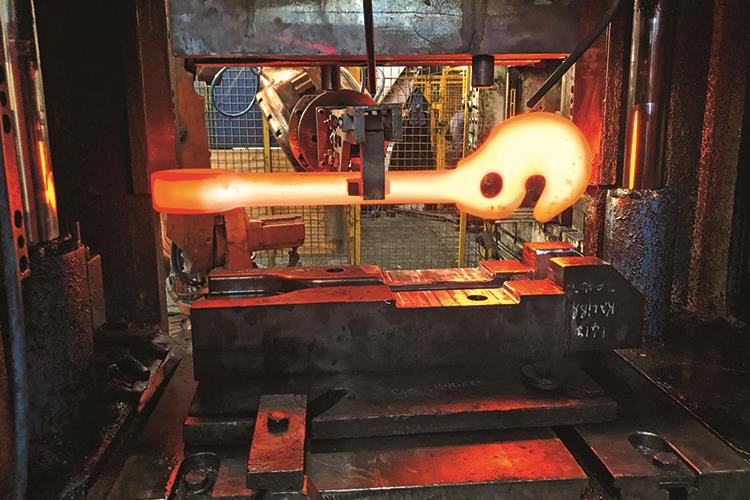

Forging

From 0.5kg up to 80kg, we provide products made from presses up to 4000 tons in hot forging. Our warm forging products, on the other hand, range between 0,4 kg up to 1,5kg.

We have a total of seventeen highly automated forging production lines, consuming 150 tons of material each day.

Heat Treatment

Heat treatment, is a very important process determining the final properties and quality of the product. Required heat treatment depending on the type of material and desired performance like quenching and tempering, annealing, normalising, T5, T6 are available under the same roof.

Machining

You may also get variaty of different products as forged, machined, welded, surface treated depending on your requirement. Our team is pleased to work on possible solutions to acomplish the best and economical alternative for your demand.

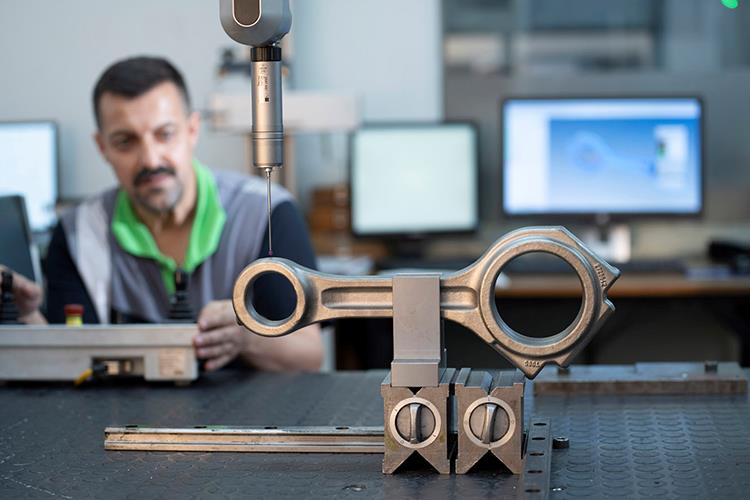

Quality Assurance

Our goal is to produce correct part at the first attemp...

To do this, we use all kinds of methods from FMEA to SPC results before production, from simulation to error catalogues. We continue to serve our customers such as Volkswagen, Toyota, Bosch, Renault, Stellantis, Ford, Borgwarner, ZF, Scania in the line with a goal of zero defect, thanks to both dimensional, mechanical and crack controls after the production process which is regularly monitored and constantly improved.

These efforts are also registered with ISO/TS 16969, ISO 9001 certificates. In addition, since we owe it to show quality not only in products but also with our respect for the environment, we have also embodied our work in this field by obtaining the ISO 14001 certificate.

Our Quality Policy: To bring competitive innovation to the running order, to increase our market share and competitiveness with the logic of continuous improvement, by doing the correct work at the first time, at the desired quality, price and on time. Internalize the satisfaction of our customers and employees.