Forging

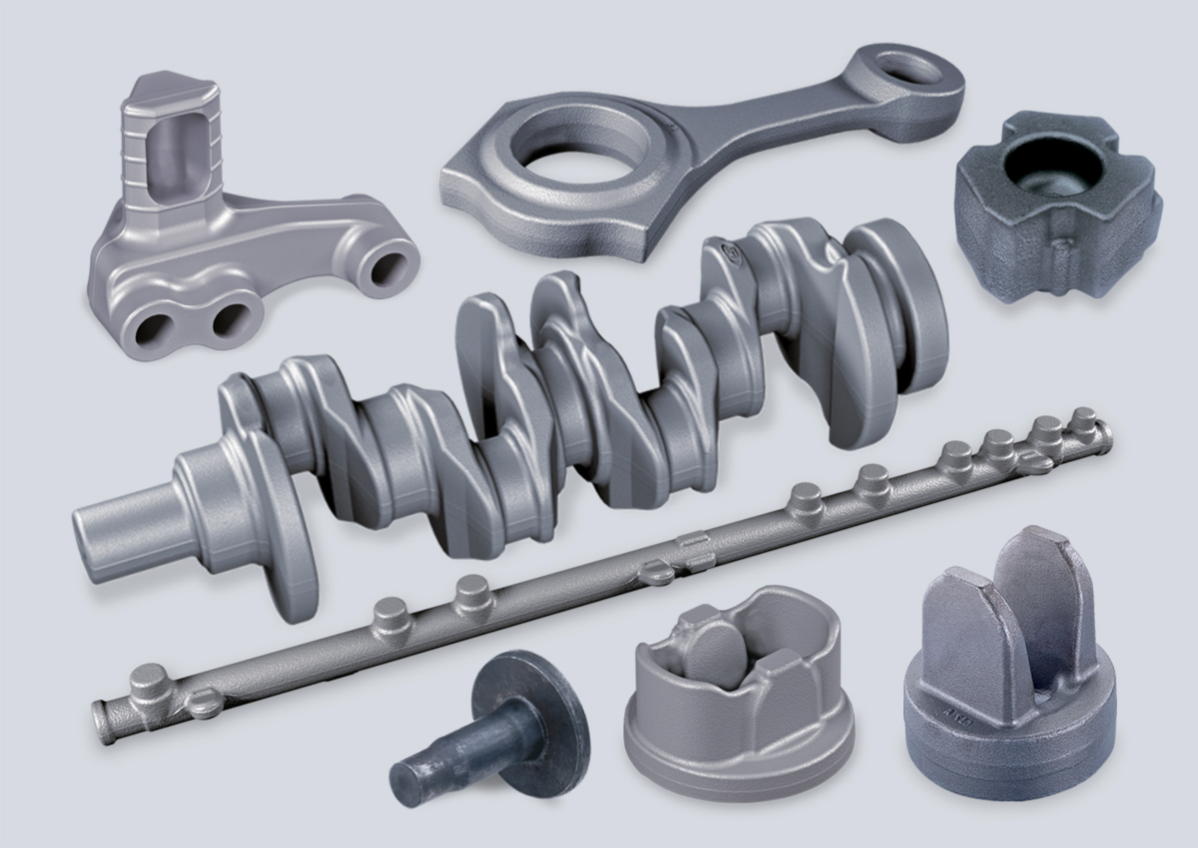

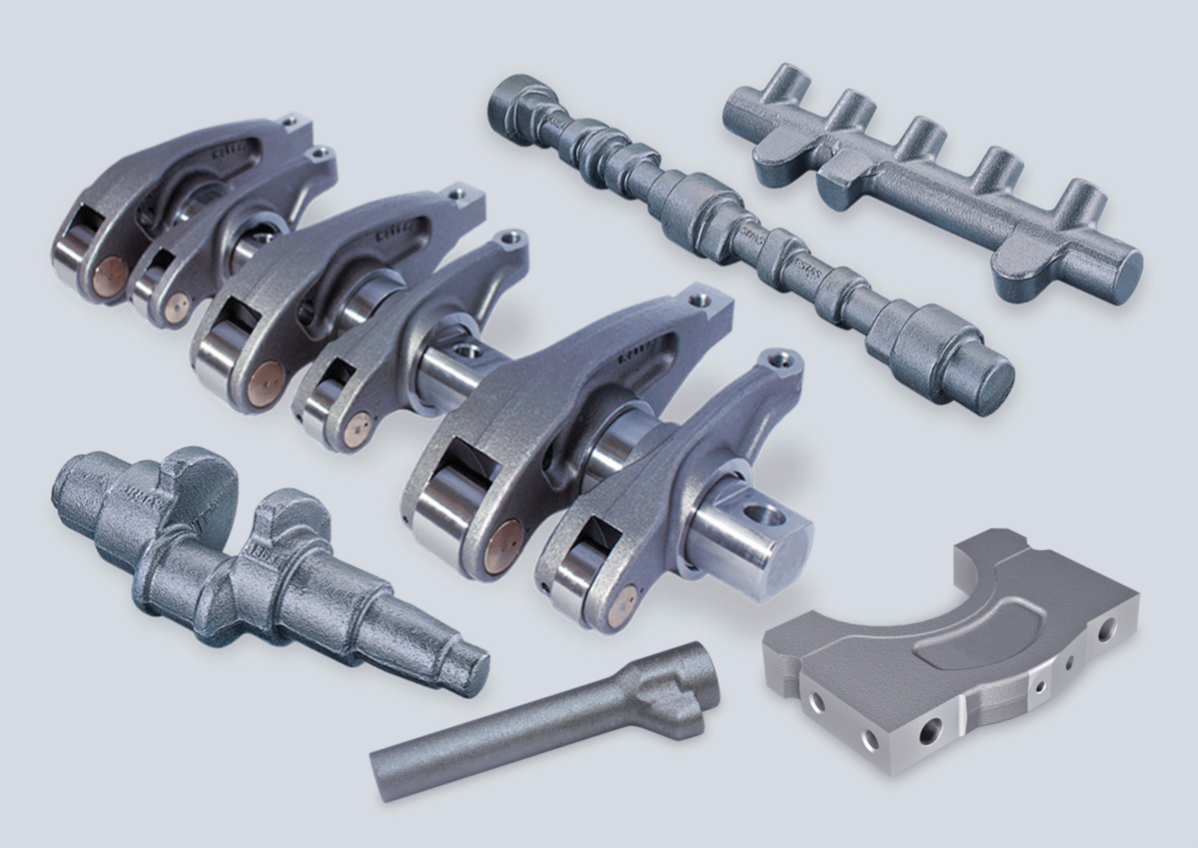

Our engineering and development activities cover our full supply services starting from a bar of raw material until finished forged part, including tool design, forging, heat treatment, machining, surface treatment, assembly and quality control.

From 0.5kg up to 80kg, we provide products made from presses up to 4000 tons in hot forging. Our warm forging products, on the other hand, range between 0,4 kg up to 1,5kg. We have a total of seventeen highly automated forging production lines, consuming 150 tons of material each day.

Eighty Robots together with transfer systems, sensors, cloud databases, vision recognitions are helping us monitor and control our processes, to achieve superior products, while preventing possible failures. Each production unit provides online data to our SAP system through SCADA (supervisory control and data acquisition) interphase.

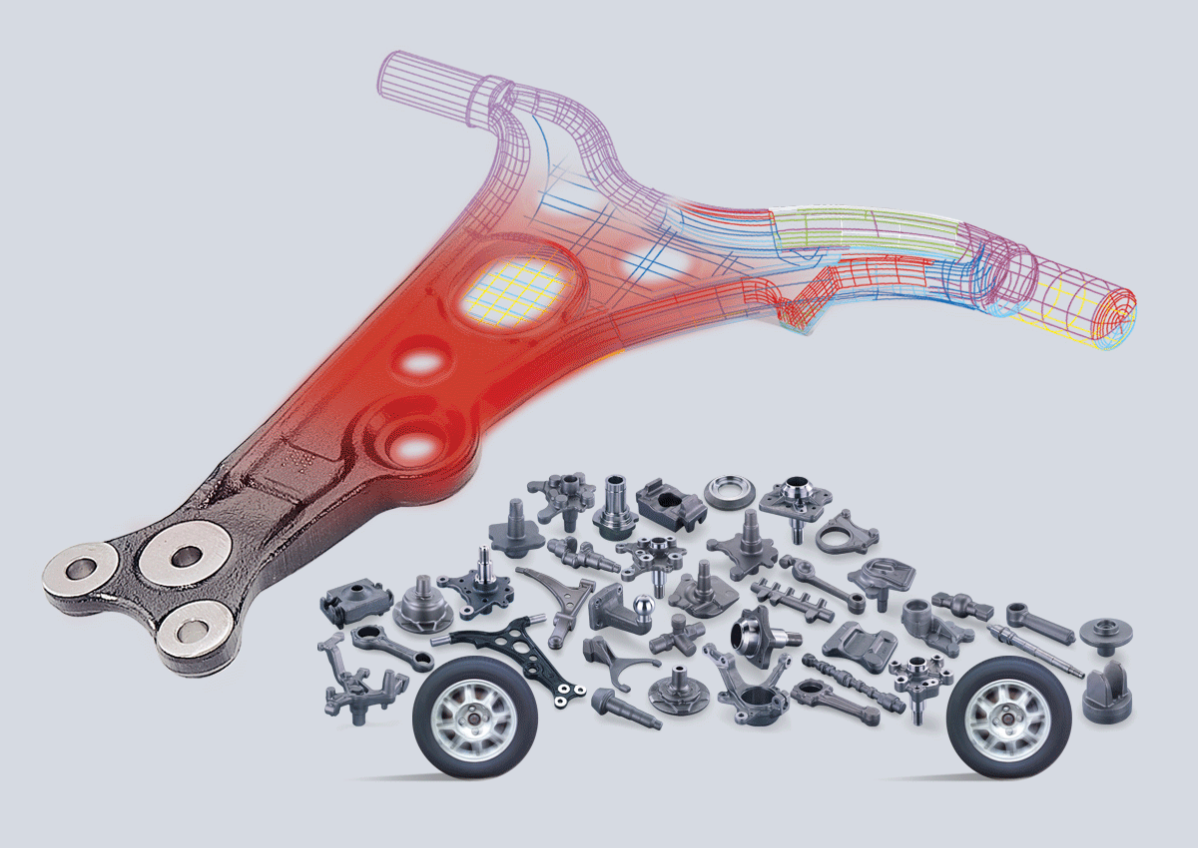

Forged Parts in Mobility

With an annual production of 20 million parts, KANCA supplies forged and machined parts to hybrid, battery-powered, gasoline and diesel vehicles.

The parts we provide are used in suspension systems, drivetrains, engines and powertrains.

Sectors

It is possible to see a piece of KANCA in all sectors where there is movement.

Passenger and commercial vehicles, construction equipment, pumps, marine industry equipment, generators and more.

KANCA stands by its customers with a wide range of solutions from forging to finished products in group of parts weighing from 0,5 kilogram to 60 kilograms.

Eco Friendly and Lightweight Products

In addition to high-alloy quality steels, KANCA offers products in strong and lightweight systems with different materials such as stainless, aluminum and titanium.

KANCA products are your reliable solution partner in every field where quality, sustainability and durability are required.